The most commonly used forming technology for alumina ceramics

2020-09-16(1744)Views

There are many molding methods for alumina ceramics, such as extrusion, injection, dry pressing, hot pressing and other molding methods.

Grouting molding method: This is the earliest molding technology of alumina ceramics. The cost is relatively low, and it is suitable for workpieces with complex shapes and large sizes. The alumina slurry of this molding method usually uses water as a medium and then adds a binder and a debonding agent. After grinding, it is exhausted and finally introduced into the plaster mold. If it is hollow grouting, when the mold wall is adsorbed to a sufficient thickness of slurry, the excess slurry needs to be poured out to reduce the shrinkage of the green body, so it is necessary to choose a high concentration slurry as much as possible.

Dry press molding method: This molding technology is only used for workpieces with simple shapes, internal thickness exceeding 1mm, and diameter and length not exceeding 4:1. There are two types of methods: single axis and bidirectional axis. The press is divided into mechanical chamber press and hydraulic press. There are fully automatic and semi-automatic forming methods. Among them, the maximum pressure of the press is 200MPA, and it can produce about 15-50 workpieces per minute. Because the stroke pressure of the hydraulic press is evenly distributed, the height of the pressed workpiece will be different when the filling powder is different.

The mechanical press is the opposite. It will generate corresponding pressure with the amount of powder filled. It is easier for the size to shrink after sintering, which affects the quality of the product. Therefore, the uneven distribution of the powder during the dry pressing process is particularly important for filling and has a great influence on the precise control of the dimensions of the alumina ceramic parts manufactured.

+MoreRelated Suggestion

-

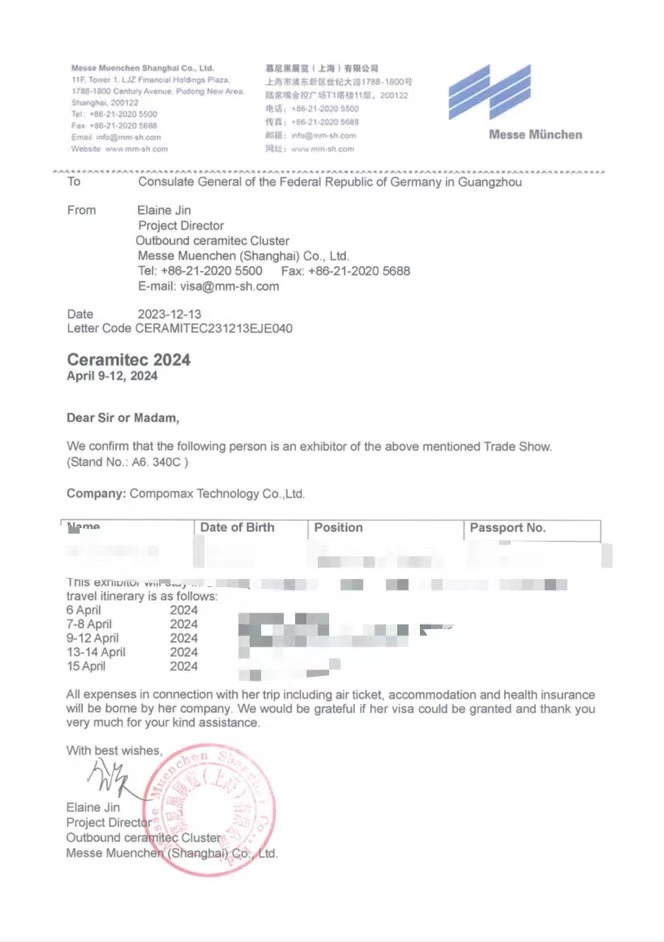

Compomax to Attend Ceramitec 2024

As a leading manufacturer of technical ceramics in China, Co...

-

PWTC Expo, the Exhibition Venue of CERAMICS CHINA 2024

From June 25-28, 2024, the 38th edtion of CERAMICS CHINA wil...

-

The eight application fields of zirconia ceramics in modern life

The non-signal shielding of zirconia ceramics is resistant t...

-

Application of Zirconia Ceramic Conversion Coating in Automobile Coating

In the field of automotive coating, phosphating is the most ...

0755-27688979

Service Hotline:0755-27688979

Phone:0086 13823743080

Fax:

Email:apricot@cpmic.com

Address: